Screw stacker and belt filter press, both of which are widely used in the field of sludge dewatering, can operate continuously, and in many cases, the two can be substituted for each other.

The working principle of the screw stacker:

The main body of the screw stacker is overlapped by a fixed ring and a floating ring, and the screw shaft runs through it, which integrates concentration and dehydration. The former section is the concentration section, and the latter section is the dehydration section.

1) Concentration: When the screw shaft rotates, multiple fixed and movable laminations around the screw shaft move relative to each other. Under the action of gravity, sewage is filtered out from the relatively moving lamination gap to achieve rapid concentration.

2) Dewatering: the thickened sludge moves forward with the rotation of the screw shaft; along the outlet direction of the mud cake, the pitch of the screw shaft gradually decreases, the gap between the rings also gradually decreases, and the volume of the spiral cavity continues to shrink; at the outlet back pressure plate Under the action of , the internal pressure gradually increased. Driven by the continuous operation of the screw drive shaft, the water in the sludge is squeezed out, and the solid content of the filter cake increases continuously, finally realizing the continuous dewatering of the sludge.

3) Self-cleaning: The rotation of the screw shaft promotes the continuous rotation of the swimming ring. The equipment relies on the movement between the fixed ring and the moving ring to achieve a continuous self-cleaning process, which cleverly avoids the common clogging problem of traditional dehydrators.

The working principle of belt filter press:

A belt filter press is a kind of filter equipment that uses two annular filter belts wound on a series of drums of different sizes arranged in sequence, and uses the extrusion and shearing action between the filter belts to remove the moisture in the slurry.

- In the pretreatment stage, the solid content of the original slurry is generally very low. In order to reduce the processing cost, gravity sedimentation or other means should be used to increase the slurry concentration. The commonly used pretreatment method of belt filter is: the thickened sludge is mixed with polymer flocculant, and under the action of flocculant, the fine particles are agglomerated and preliminarily precipitated, which is the preparation condition for sludge dewatering.

- In the gravity dehydration stage, the belt filter adds the flocculated pretreated sludge to the filter belt. Under the action of gravity, the free water outside the floc is filtered out through the filter belt, thereby reducing the water content of the sludge.

- In the wedge-shaped pre-pressing dehydration stage, the sludge begins to enter the wedge-shaped pressing section after gravity dehydration, and the gap between the filter belts gradually decreases, so that the sludge begins to be squeezed and sheared, and then dehydrated again. After this stage, the fluidity of the sludge is almost completely lost, thus ensuring that the sludge will not be squeezed out in the pressing and dewatering section under normal circumstances.

- In the pressing and dewatering stage, the belt filter repeatedly presses and shears the sludge through a well-designed press roll system, removes a large amount of capillary water, and gradually reduces the sludge moisture to form a sludge filter cake. The filter cake is scraped off by the discharge scraper at the separation of the re-selection filter belt, and the discharged filter cloth enters the next cycle after being cleaned.

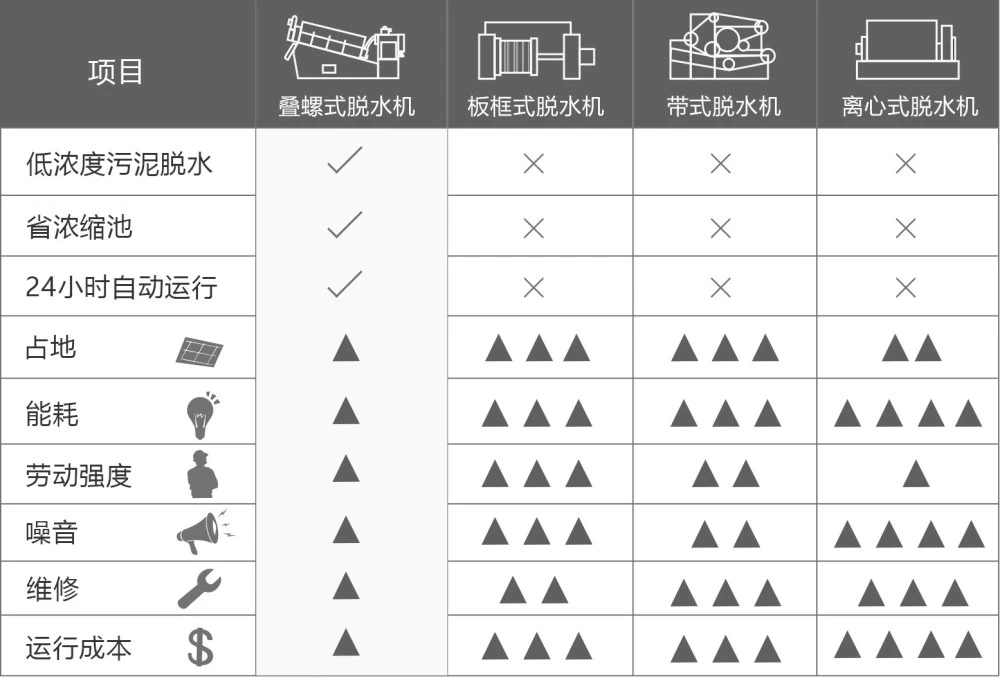

Comparison of the advantages of screw stacker and belt filter press:

The advantages of screw stacking machine:

- The screw stacking machine is suitable for the dewatering of high and low concentration sludge, without the need to build a concentration tank, reducing the construction cost, reducing the release of phosphorus and the generation of odor.

- No blockage, reduce flushing water consumption, save water costs, and reduce the burden of internal circulation caused by the backflow of cleaning water.

- The electric control cabinet, the flocculation mixing tank and the dewatering main body are integrated, which reduces the floor space and is simple and convenient to install.

- Realize fully automatic 24-hour operation, reducing the labor intensity of operators.

- The running speed of the screw shaft is low, 2-3 revolutions per minute, the power consumption is low, and there is basically no vibration and noise on site.

- The body is almost entirely made of stainless steel, which can greatly extend the service life.

Advantages of filter press:

- Low power consumption and large processing capacity.

- High dehydration efficiency and high solid content of mud cake.

- Simple operation and management, easy maintenance.

- High degree of automation, continuous production.

- Low noise and long service life.

- Can deal with inorganic sludge.