- Category / type: MBBR

- Application: Urban sewage and industrial wastewater treatment.

- Material: concrete, polyethylene, polypropylene, glass-reinforced plastic (GRP).

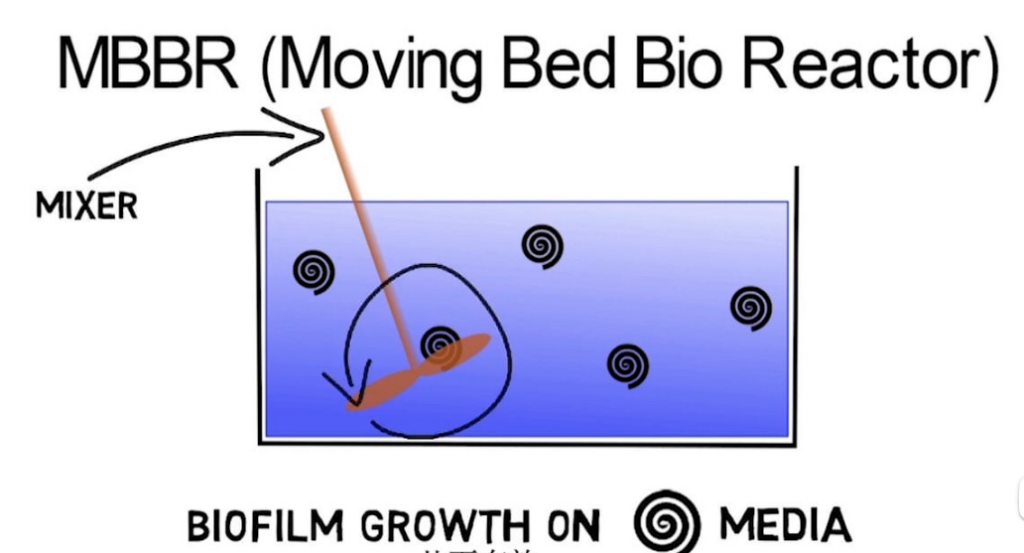

What is MBBR?

Moving bed biofilm reactor (moving bed biofilm reactor) MBBR was proposed for the first time by Germany Linde AG Co., Ltd., by adding specific suspended fillers to the ordinary activated sludge tank to improve the volumetric load rate and effluent index of sewage treatment, and enhance the tolerance of the system to high salinity, toxic and harmful compounds.

MBBR combines the advantages of traditional activated sludge method and biological contact oxidation method. Suspended fillers in the reactor move freely because of stirring. When sewage passes through the reactor with moving fillers continuously, biofilms grow on the fillers and purify water quality through the adsorption and biological oxidation of suspended activated sludge and carrier biofilms.

MBBR scope of application:

- Strengthening denitrification and phosphorus removal and upgrading of sewage treatment plants.

two。.

Solve the problem of excessive ammonia nitrogen at low temperature in winter. - The capacity of the sewage treatment plant can be expanded up to 3 times.

- Treatment of high concentration, toxic and refractory organic compounds.

- Advanced treatment of sewage treatment plant and industrial wastewater.

At present, the mainstream MBBR process:

1.Linpor MBBR process: including three kinds of Linpor-C; Linpor-C/N; Linpor-N.

2.Kaldnes MBBR process, including PMI MBBR, HYBAS-MBBR; BAS-MBBR, etc.

3.Levapor is actually an upgraded version of the first two, which has functions for the first two and can improve twice the efficiency, especially in the treatment of high concentration and refractory organic compounds. - The difference between the three is mainly the carrier.

MBBR vector:

- Moving bed biofilm reactor (moving bed biofilm reactor) MBBR was first proposed by German Linde AG Co., Ltd. Dr. Morper proposed MBBR packing and system process. The core of MBBR process is high efficiency polyurethane biological carrier, which is named Linpor carrier.

- Kaldnes in Norway has developed another set of MBBR technology system, whose biological carrier is mostly made of polyethylene and has a Bauer ring structure.

- Bayer in Germany has developed Levapor carriers and their corresponding MBBR processes suitable for high concentration of refractory organic matter and high ammonia nitrogen and nitrate, which have been applied to chemical, pharmaceutical, pesticide and other wastewater treatment.

- MBBR began to study in the mid-1980s, and since the 1990s, there have been more than 400 sewage treatment plants based on this technology, including municipal sewage and industrial wastewater treatment.