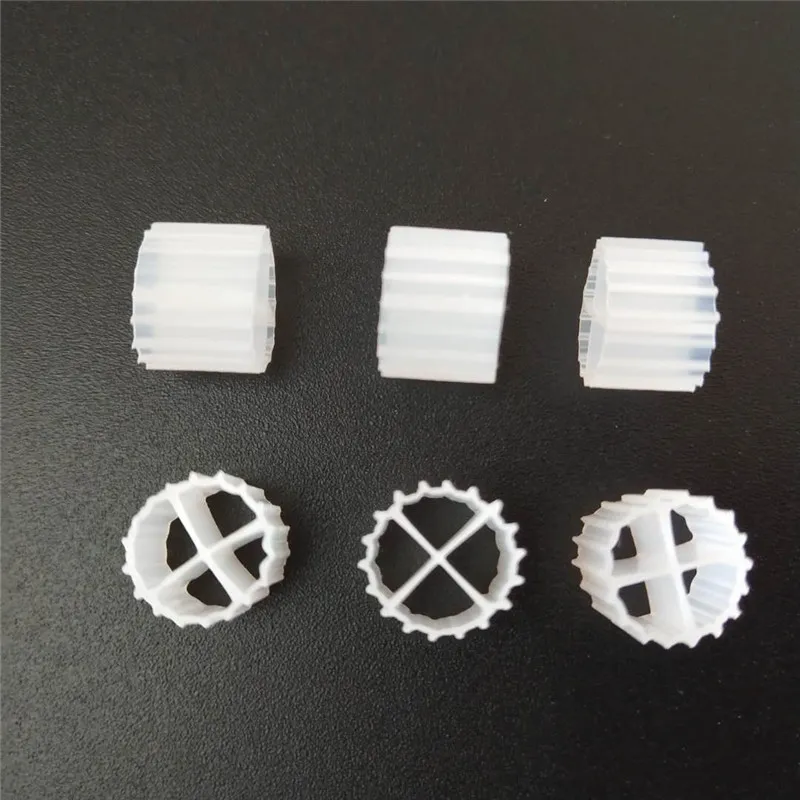

Moving Bed Biofilm Reactor MBBR Media

Bio filter media, used in Integrated Fixed-lm Activated Sludge (IFAS) and moving bed biofilm reaction (MBBR) system.

Contact us to get !

- Free design suggestions

- Product Technical details

- Full product catalog

Moving bed biofilm reactors for wastewater treatment

MBBR filter media is a novel biologically active carrier, it adopts scientific formula, depending on the nature of water, blending a variety of beneficial microorganisms grow quickly attached trace elements in polymer materials, through a special process modification, constructed, with more than large surface area, hydrophilic, high biological activity, biofilm fast, good effect, good impact resistance.

Typical Applications

It can be used in different stages of sewage treatment process, such as aerobic pond, anaerobic pond, anoxic pond, sedimentation pond, etc. It is not limited by the shape of the pond and can be used in various filter types.

Packing and Delivery

- 0.1cbm/bag

- 20GP=28-30cbm

- 40GP=60cbm

- 40HQ=68-70cbm

Our product Advantage

- Large adhesion specific surface area and high biomass

- Special formula and modification to accelerate biofilm formation

- Rapid removal of ammonia, nitrogen and phosphorus to improve effluent

- Flexible, stable and easy to operate

- Save energy consumption and occupy land,Easy to maintain

- Special shape and structure to increase life

- Strong impact load capacity, increase load

Production lines

Technical Parameters

| PE01 | PE02 | PE03 | PE04 | PE05 | PE06 | PE07 | PE08 | PE09 | |

| mm | φ12*9 | φ11*7 | φ10*7 | φ16*10 | φ25*10 | φ25*10 | φ5*10 | φ15*15 | φ25*4 |

| nos. | 4 | 4 | 5 | 6 | 19 | 19 | 8 | 40 | 64 |

| m2/m3 | >800 | >900 | >1000 | >800 | >500 | >500 | >3500 | >900 | >1200 |

| g/cm3 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 1.02-1.05 | 1.02-1.05 | 0.96-0.98 | 0.96-0.98 |

| pcs/m3 | >630000 | >830000 | >850000 | >260000 | >97000 | >97000 | >2000000 | >230000 | >210000 |

| % | >85 | >85 | >85 | >85 | >90 | >90 | >80 | >85 | >85 |

| % | 15-67 | 15-68 | 15-70 | 15-67 | 15-65 | 15-65 | 15-70 | 15-65 | 15-65 |

| days | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 | 3–15 |

| gNH4-N/m3.d | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 500-1400 | 500-1400 | 500-1400 |

| gBOD5/m3.d | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2500-15000 | 2500-15000 | 2500-20000 |

| gCOD/m3.d | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2500-20000 | 2500-20000 | 2500-20000 |

| ℃ | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

| year | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 |